How to Eliminate Brake Noise

Are your 4×4 brakes producing a screeching sound every time you put your vehicle to a stop? It may not affect much of its performance but it can be annoying for you and your neighbors, if it frequently occurs.

In this article, we give you some of the main causes of a brake noise and how to get rid of them for good.

Brake noise happens when one of the brake components comes in contact with the rotor. Imagine that you’re going 40 miles per hour and you suddenly step on your brakes. The caliper instantly presses the brake pads on the rotor which hinders your vehicle’s movement.

Now, there will be instances when brake pads touch the rotor’s surface but the rotor itself creates a wobbling or “wriggling” effect that leads to friction irregularities which produce brake noise.

WHAT ARE THE MAIN CAUSES OF BRAKE NOISE?

Brake noises can be irritating if they’re persistent. Truth be told, brake noise is one of the most common complaints among vehicle owners, with an estimated 1 in 3 drivers experiencing it at some point. Which is why, it matters that you go straight to the heart of the problem. Some main causes of brake noise are:

- Worn-out brake pads

- Dirty pads and rotors

- Excess moisture

- Aggressive braking style

- Lack of drum brake lubricant

WHAT ARE THE BENEFITS OF ELIMINATING BRAKE NOISE?

Eliminating or at least reducing the amount of brake noise may result in the following:

- Lets you pay more attention to your driving environment.

- Gives you a comfortable ride.

- Less sound means less agitation.

WHAT ARE SOME EFFECTIVE METHODS FOR ELIMINATING BRAKE NOISE?

If you are experiencing brake noise, have your brakes inspected by a qualified technician to determine the cause and find the best solution. Eventually, you’ll work together to perform the needed action.

Replace Worn-out Brake Pads and Rotors

When you place a new brake pad on a table in lying down position, it consists of the backing plate on its side and you’ll notice its braking part on top. But for an old one, only the backing plate is visible.

Standard brake pads can be difficult to determine whether they’re overused or not because you still need to detach the wheels and look at them closely.

On the contrary, the premium variants have wear indicators or metal clips that stick out passed the backing plate. So by the time your brake pads wear out at 2-3mm, they screech against the brake rotor, signaling the brake pads must be replaced.

As for the rotors, they wear out in the smooth, middle part. However, the wearing out doesn’t affect the sides that later on reveal edges. The problem with the edges arises when they begin to rust and comes in contact with the pads. If the rust on the edges isn’t too much, you may use a sandpaper to remove it on the rotors. But if it is, it’s mandatory to replace them.

Refer to Repair Pal’s table below for brake parts replacement costs and other charges. Take note that such costs depend on factors like where you live and what your 4×4 model is.

Average Replacement Costs

| Task | Price Range |

| Brake Pad Replacement & Rotor Resurface | $235-$329 |

| Labor | $158-$200 |

| Purchasing Parts | $77-$129 |

In case some of you are wondering, there’s a minimum thickness that’s specific to every rotor. For example, a new Jaguar rotor is 24mm at best and has a minimum thickness of 22mm. Use a digital caliper for this part and if the result shows anything within the acceptable range, it means your rotors are still okay.

Replace Filthy Brake Pads and Rotors

Rotors that have many grooves or “trail marks” means they’ve gone through a lot of beating. This happens when dirt gets stuck and squished between the pads and the rotors. This can be from saw dust to small rocks that can get through, but poor-quality brake pads with rough, scratchy surfaces can also be the culprit.

Another thing that can be an issue are rusted rotors. Rust is formed on the rotor surface when water accumulates on it for quite some time. Geographical location normally plays a primary factor here, especially if you live in muddy or swampy places.

A little amount of rust won’t be such a big deal but if you rarely use your 4×4, a huge amount of it means it’s time you give the rotor a go or in worse cases, it should be replaced.

For the brake pads, they don’t easily get dirty unlike the rotors. So you may use a sandpaper as well to remove minor rust or other dirt forms. But if your brake pads are exaggeratedly dirty (i.e. with groves just like the rotors), you need to buy new ones.

Don’t forget that new and oily rotors can also get in the way. Manufactures coat new rotors with oil to protect them against rust while inside their packages. On the other hand, you need to remove it by the time you install the rotors because you don’t want to compromise your brakes’ safety. Using either a brake cleaner or plain, soapy water works fine in removing the oil. Wipe it off with a clean cloth or towel and make sure to clean both sides of the rotors.

While it’s okay to put a brake cleaner on the rotors, the same thing can’t be done on brake pads. This is because a brake cleaner can cause brake pad swelling and damage, especially on their rubber backing and can be a rust agent, too.

If you accidentally put a brake cleaner on the brake pads as long as it isn’t much, you can just rinse it off with soapy water.

Put On a New Brake Hardware

The brake hardware is anything that you can see in and around the brake pads and caliper. To put it simply, the brake hardware appears to be a clip that lets the brake pads silently rub against the caliper. As your brake pads wear out, the same thing goes for your brake hardware. In turn, it also produces noise and too much brake wear.

This doesn’t only occur on disc brakes but also on drum brakes. If you look at a drum brake interior, the moment you step on the brakes, the wheel cylinder pushes the shoes in an outward motion towards the walls until your 4×4 stops. Once you let go of the brakes, the wheel cylinder goes back in place to get rid of the resistance.

When your brake hardware is worn out or absent, the shoes have a tendency to rub off the drum even though your foot isn’t touching the brake. So it all comes down to replacing your brake hardware with a new one.

Take note, some 4x4s don’t use the usual brake hardware and use pin bolts, instead. If this is the case, use any brush to remove visible dirt on the contact point between brake pads and caliper. The task’s easier if you’re using a rotary tool.

By the way, when you replace a rotor, don’t forget to use a wire brush to get rid of dirt and excess rust on the hub or holder. This is because rust can cling to your new rotor and cause it to easily wear out. Afterwards, apply an anti-seize on it for rust protection and quick motor removal next time.

Apply Some Lubricants

Lack of lubrication creates resistance on brakes and other related parts that also leads to an irritating sound. There are 2 types of lubricants that you can use – the copper anti-seize is used to smoothen contact points between brake pads and caliper, while the silicone paste is used on guide pins for a seamless, sliding movement.

Copper anti-seize is good for brakes because it can withstand varying amounts of pressure. In other words, it only bends and doesn’t become brittle.

What are the areas of lubrication?

- Brake caliper bracket

- Contact points between the brake pads and guide (top and bottom)

- Identical spots where brake pads are found

- Brake hardware top

- Back of brake pad

Avoid putting too much anti-seize because it collects dirt so putting a small amount is enough to get the job done.

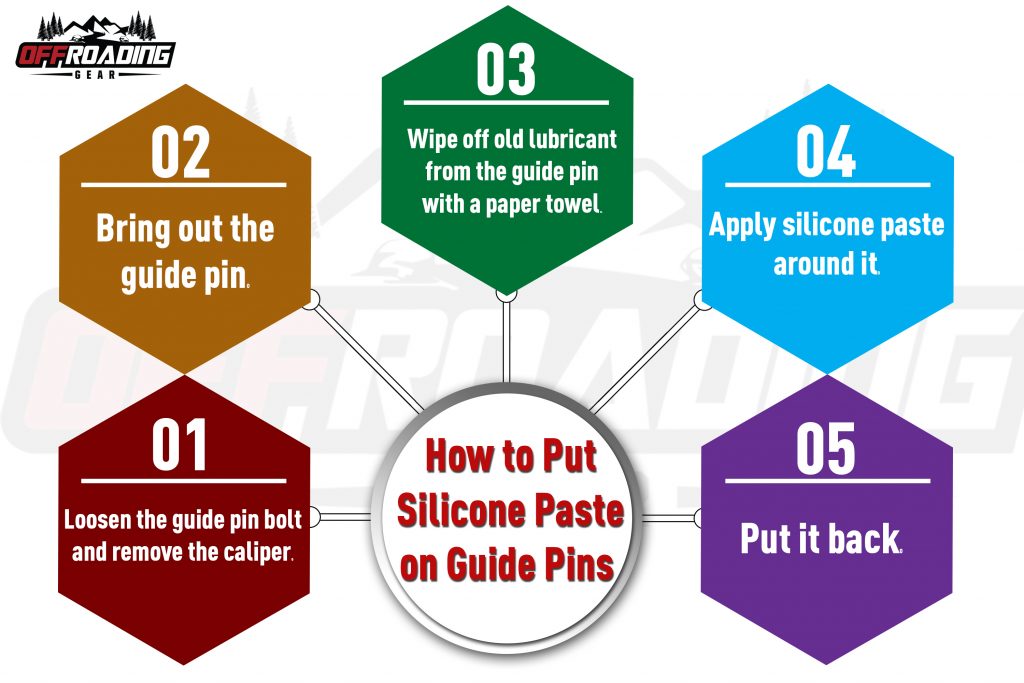

In terms of the guide pins, they should be properly lubricated to ensure they slide well with the caliper which is where the silicone paste comes in.

This is because it endures the brakes’ heat and prevent damaging the rubber dust boots. For clearer details, check out ChrisFix’s Channel.

Replace Rusted Dust Shield

The dust shield is the thin metal plate at the back of the rotor that automatically blocks dirt, water and small rock pieces from penetrating the suspension area to avoid congestion.

Over time, the dust shield’s bendable metal part due to external forces is what causes a scraping noise that can also be very disturbing. Sometimes, it’s also due to rust just like on the rotors.

If the dust shield isn’t badly covered in rust, you may have it resurfaced with a sandpaper. Otherwise, it also means it’s destined for a replacement.

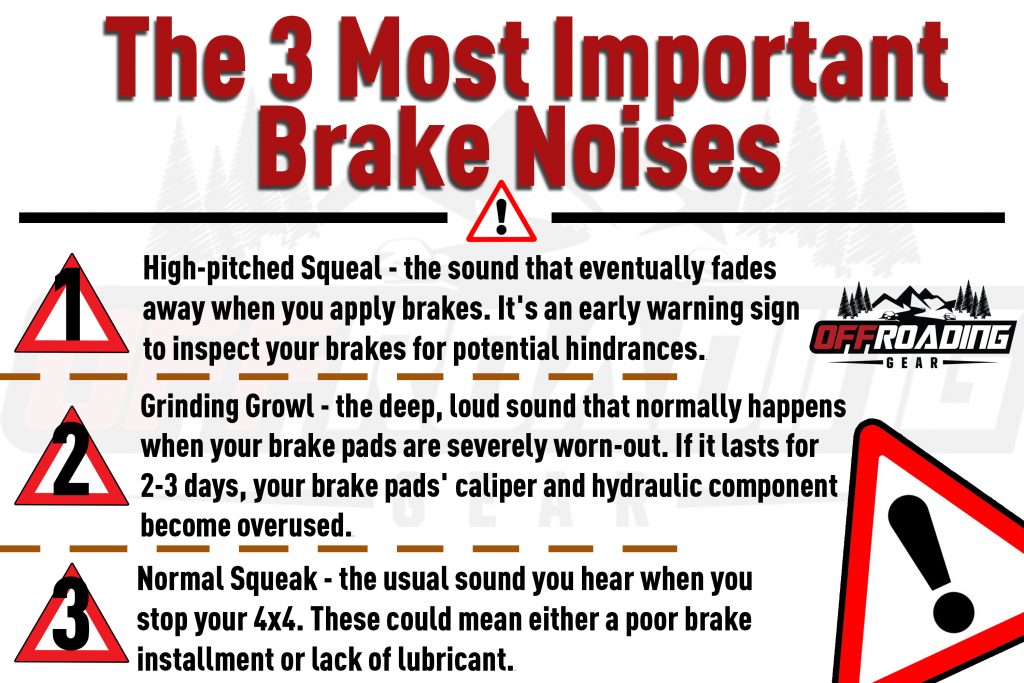

Brake noises are downright irritating when you hear them but did you know that you can also get a benefit from them?

Brake noises tell the condition of the brakes based on the type of sound they produce. They inform you whether it’s time to buy new brake parts or just have regular maintenance checks.

More explanations on brake noises are found on Angie’s List.

WHAT ARE THE CONSEQUENCES OF IGNORING BRAKE NOISE?

If you ignore the brake noise, it can develop into something serious later on which can incur:

- Further rotor damage

- Road and off-road accidents

- Driving discomfort

POSSIBLE FAQS

1. Can road grime affect brake noise?

- Brake noise can be eliminated by cleaning the brake pads and/or rotors.

2. Can brake noise be reduced by using a special brake fluid?

- Brake noise can be eliminated by using a brake caliper lubricant.

3. Can cleaning the brakes reduce brake noise?

- Yes but if cleaning doesn’t work, brake noise can be eliminated by replacing the brake pads and/or rotors.

CONCLUSION

Noisy brakes don’t translate to extreme danger. However, they’re more of an irritant which can cause you and others to lose concentration on valuable tasks. By having the brake components resurfaced or replaced, you prevent unnecessary distractions from getting the best of you. Share us your experiences by commenting below.